BOX 101

BOX 101

Everything you need to know about boxes! Skip ahead to one of these sections:

The Pratt Advantage

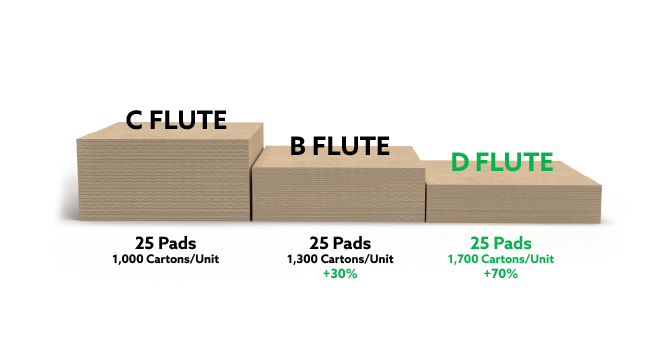

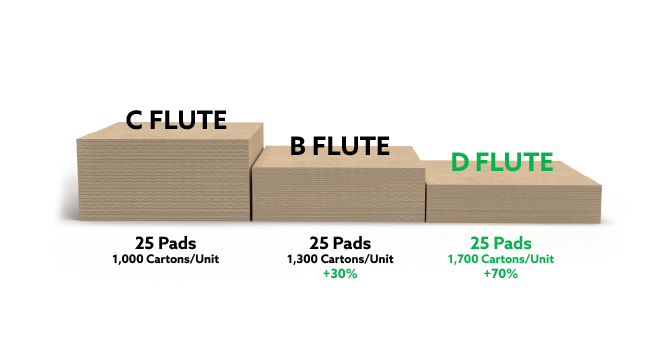

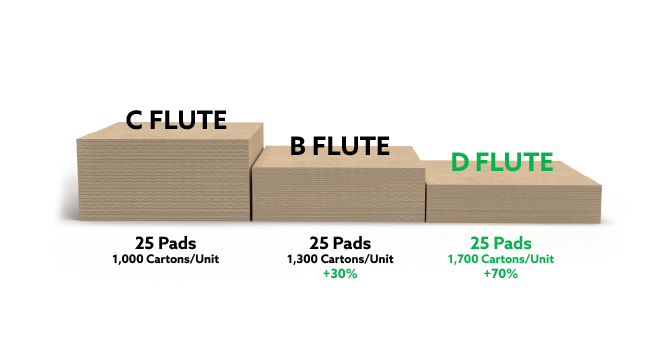

GET MORE PRODUCT ON A TRUCK WITH D FLUTE

The Pratt Advantage

GET MORE PRODUCT ON A TRUCK WITH D FLUTE

More than just a box...

Corrugated boxes can be used to ship just about everything from sweet potatoes and peaches to automotive parts.

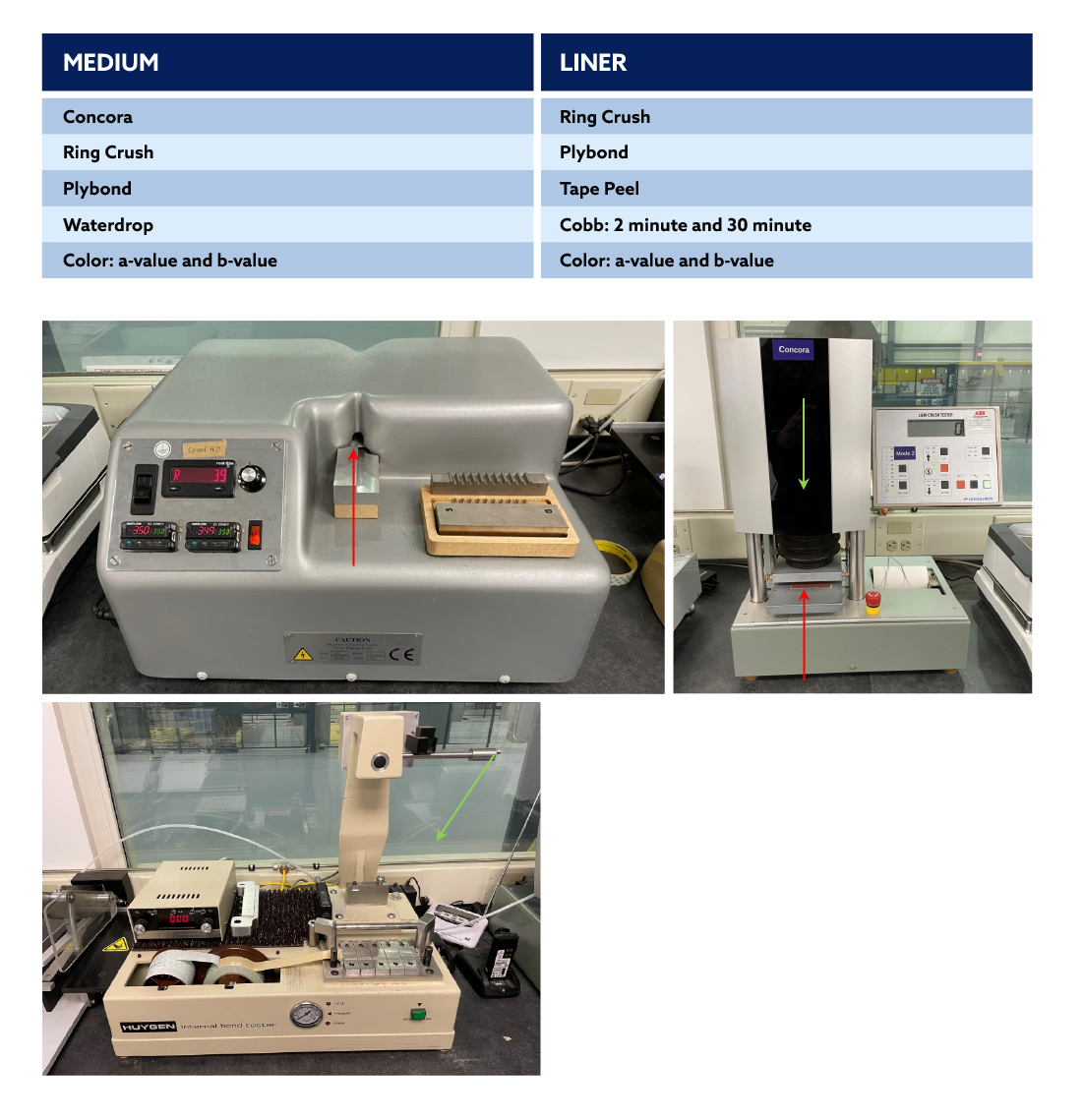

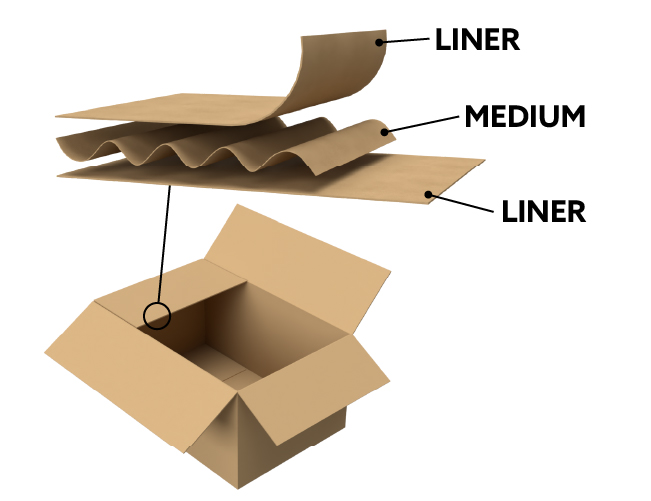

What is Corrugated Containerboard?

Corrugated containerboard is created by using two components: a liner and a medium.

LINER:

Flat material usually placed on the outer surfaces of containerboard that adheres to the medium.

MEDIUM:

Paper formed into flutes (arches) and glued between the linerboard facings.

ADHESIVE (STARCH):

- Water

- Pearl starch

- Caustic soda

- Borax

- Resin waterproofing

Corrugated Box Characteristics

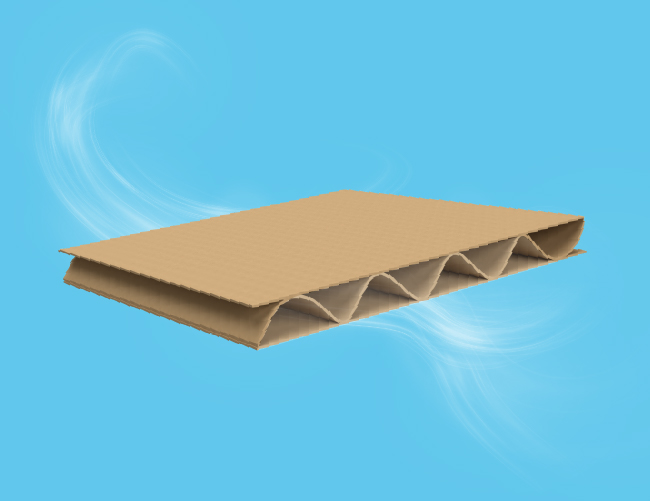

Made from corrugated paper that contains rows of air columns.

Air columns act as a cushion for any items inside of the box.

The ridges (flutes) provide additional strength and flexibility.

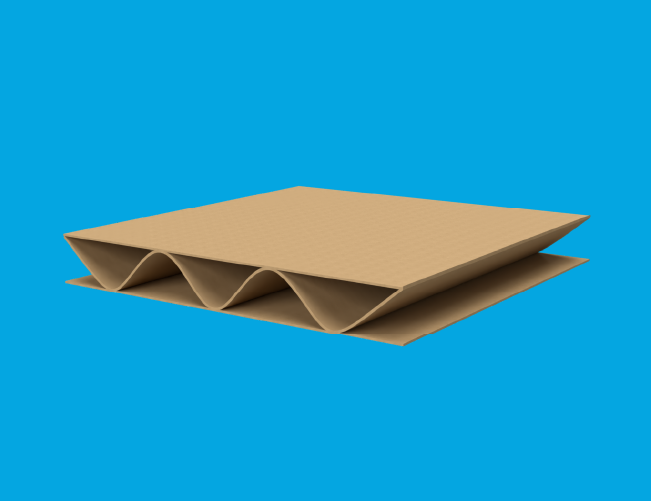

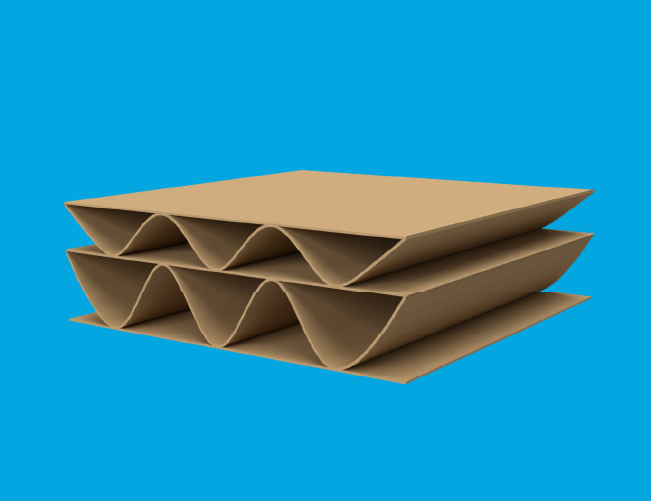

Combined Board

What is combined board? Combined board is a fabricated sheet assembled from several components such as corrugated or solid fiberboard.

Singleface

Singlewall

80% of all corrugated products

Doublewall

Triplewall

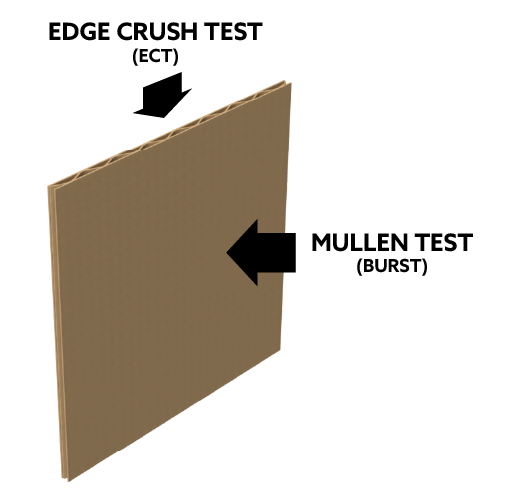

ECT vs. MULLEN

MULLEN (Rule 41)

- Measures sidewall burst

- Standardized grades

ECT - Edge Crush Test (Alt. Rule 41)

- Measures top to bottom compression

- Performance based

Typical Board Grades:

32C

44C

32B

32D

32E

48BC

51BC

67 CAA

90 CAA

112 CAA

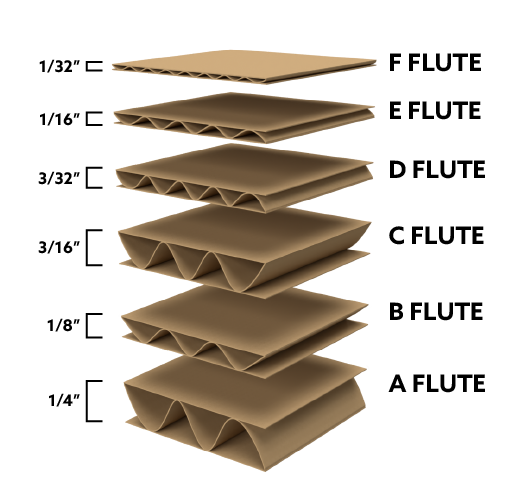

FLUTES

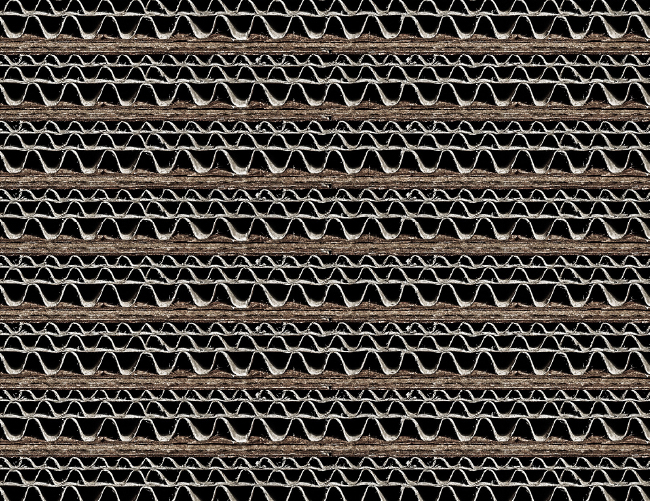

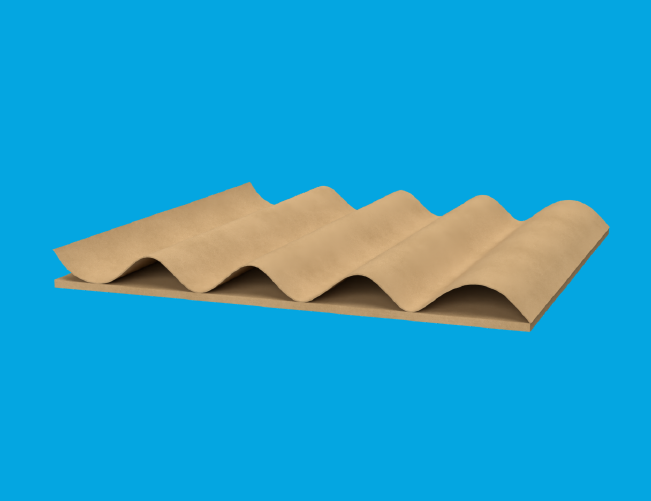

Flutes are the wave shapes pressed into a corrugated medium.

TYPES OF COMBINED BOARD

- Common Singlewall Flutes: A, B, C, D, E

- Common Doublewall Flutes: BC, BE, DE, AC

- Specialty Flutes: F, N, Other Microflutes

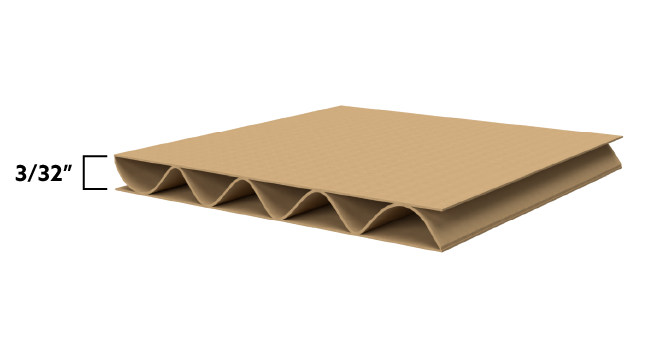

B FLUTE

47 Flutes/Linear Ft.

Qualities

- Most common type of fluting

- Excellent crush resistance and printing surface

- Good puncture resistance

- Scores and slots easily

Common Uses

- Inner packaging like pads and partitions

C FLUTE

41 Flutes/Linear Ft.

Qualities

- General all-purpose fluting

- Good printing surface, compression and crush resistance

- Good stacking strength

Common Uses

- Most common flute used for shipping boxes

- Used for its structural strength

- Used for glass, furniture, food, etc.

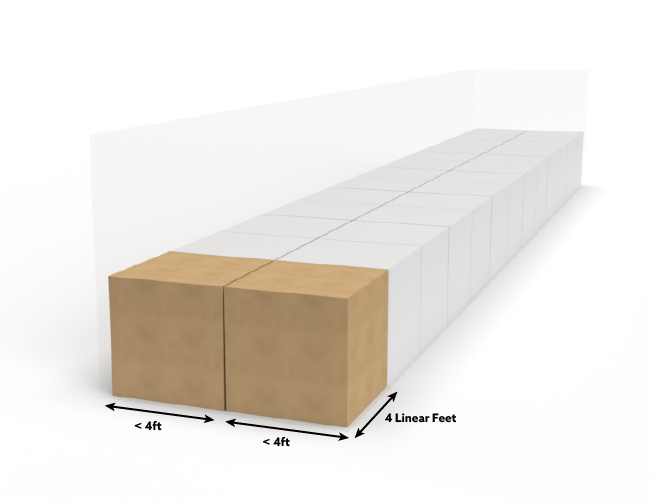

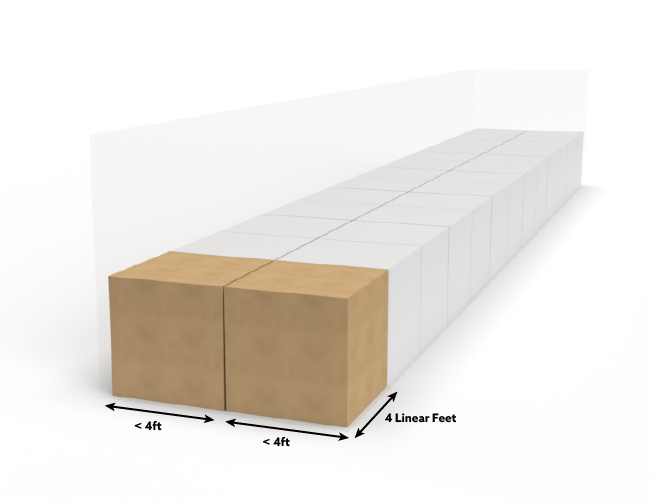

D FLUTE

63 Flutes/Linear Ft.

Qualities

- Versatile and cost-effective option for many types of packaging

- Superior print surface

Common Uses

- Excellent for e-commerce, pizza boxes and beverage boxes

Smaller and more compact

Smaller and more compact saves space and weight which may save money

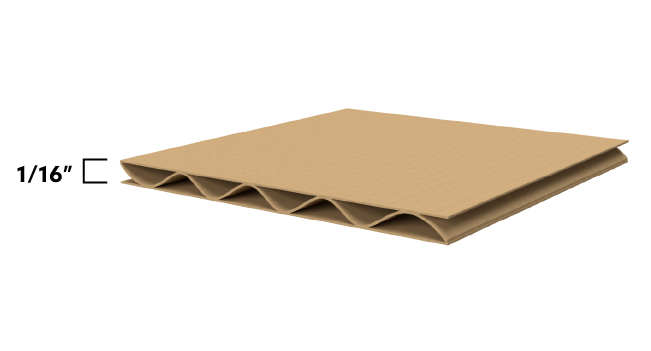

E FLUTE

91 Flutes/Linear Ft.

Qualities

- Very fine fluting

- Excellent crush resistance

- Exceptional printing surface

- Thin construction helps to reduce storage space

Common Uses

- Consumer goods packaging for items such as cosmetics, glass and ceramics

- Used for displays, ballot boxes and pizza boxes

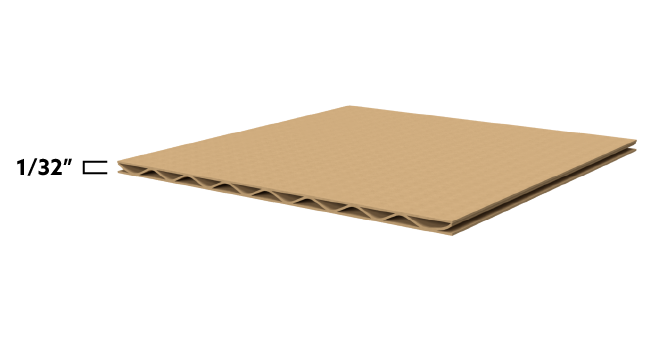

F FLUTE

128 Flutes/Linear Ft.

Qualities

- Outstanding print surface

- Excellent crush resistance

- Thin construction allows for stiffer boxes with less fiber

Common Uses

- Consumer goods packaging for items such as cosmetics, jewelry and shoes

- Used for software packaging

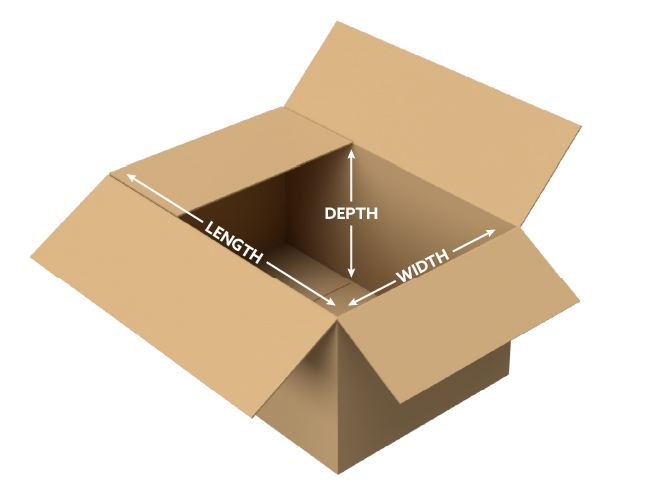

Box Measuring

Accurate inside dimensions are needed to ensure proper fit of the product. Exterior dimensions are needed for proper palletizing and distribution. Expect to be asked which dimension is the most important.

Dimensions are given in a specific order as Length, Width, Depth (or internationally as Length, Breadth and Height). Viewed from the position of the opening of the assembled box, there are four sides. In general, the longest two sides indicate length. The shorter two sides indicate width. The measurement from the opening to the bottom of the box is its depth.

Top Loading Box:

- Rectangle with two sets of parallel sides (standard shipping box)

- Length: Longest side, Width: Shorter side, Depth: Perpendicular from the four sides, from opening to bottom.

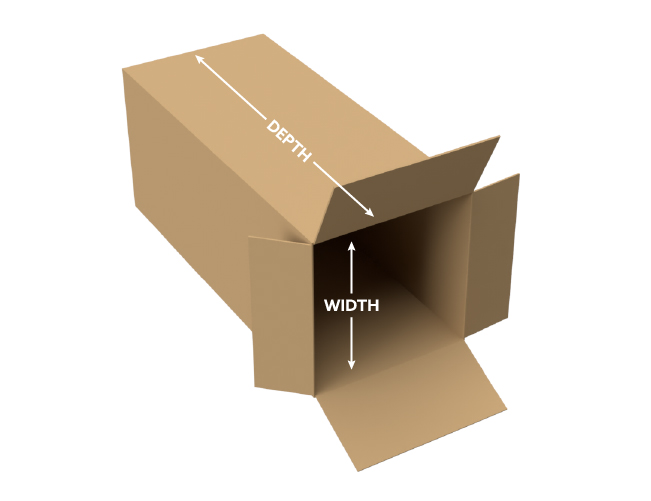

End Loading Box:

- Opens from one long end (for shipping or specialized uses)

- Length: N/A, Width: Measure of one side of the opening, Depth: Perpendicular from the four sides, from opening to bottom.

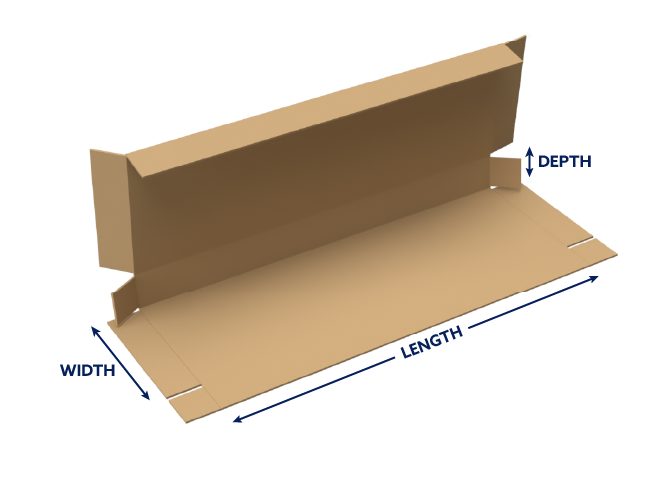

Five Panel or Wrap-Around Box:

- Includes an additional flap that overlaps or inserts securely into the sides (pizza box or tuck-in style).

- Length: Measurement of the opening ‘mouth’ of the assembled box from side to side, Width: How far back the assembled box goes from the opening.

- Depth: Perpendicular measurement of the walls from the top of the open assembled box to the bottom.

RSC Regular Slotted Container

All the flaps are the same length. The two outer flaps (normally lengthwise) are one-half of the container’s width to meet at the center when the box is folded. A fill-in pad can be placed between the bottom two inner flaps for added protection. A highly efficient design, with little manufacturing waste. The most commonly-used style.

HSC Half Slotted Container

Same as the Regular Slotted Container (RSC) without one set of closing flaps.

FOL Full Overlap Slotted Box

All the flaps have the same length as the width of the box, so that flaps come within one inch of complete overlap. This style is especially resistant to rough handling and provides additional cushioning when stacked flat. Stacked on its side, this provides extra stacking strength.

Snap or 1-2-3 Bottom Container with Tuck-In Top

Four die-cut panels intersect to form the bottom. May not be suitable for heavy items because the bottom is not fully secured. Quick to assemble, convenient for small volume shippers.

A Folder (or folder-type box) is made in a single sheet that has a solid bottom surface and is cut to be folded around the sides and top of a product placed within.

One Piece Folder (OPF)

Cut in a squared cross shape so that all four sides fold up and over. Best for shipping fragile items such as artwork, or for books.

Wrap Around Blank

Cut in one elongated board with multiple folds, each with a folding side panel. Used by automated equipment to wrap a product tightly. The finished product on its side has an unbroken top and bottom, and only the sides are flapped. Different from an RSC (‘standard’ box style) because it can be made to fit the product exactly.

Five Panel Folder (FPF) or Harness Style Folder

One elongated and scored board with a fifth panel for tucking. When folded together, every side has double board protection for better stacking or shipping of articles that could pierce the sides. Good for long or heavy flat items such as a golf club, fishing pole or hacksaw.

Roll End Tray with Locking Cover

A one-piece, elongated, scored, folding rectangular style that makes a box with strong sides and a connected lid that tucks securely. For bakery boxes, medical supplies, shoes.

Display Tray or High Wall Tray

A single elongated board with three folding pieces and adjoining side pieces. It forms a sturdy tray with walls, but no cover. Used for sales displays or where goods are sold ‘by the case.’

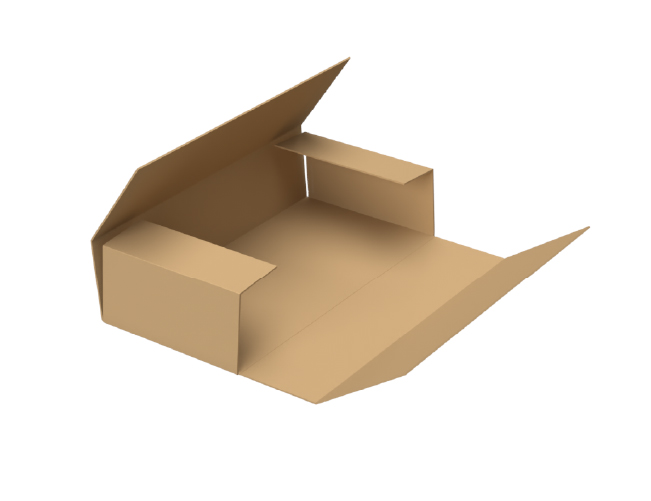

Self-erecting boxes are stored flat, but some panels are pre-glued for fast, easy assembly.

Pre-Glued Auto Bottom with RSC Top Flaps

The bottom is pre-glued, while the top panels are the same as a regular slotted container. (For a telescope style, two self-erecting containers can be used for top and bottom.)

0606A Rigid Box (Bliss Box)

Single elongated, cut and scored board plus two separate side panels. There is an unbroken bottom, the side panels are slotted into place, and the rest of the board folds around it, including small flaps overlapping the side panels. The flaps are glued to the side panels at the plant. Center-meeting flaps make up the top. This box is rigid and very sturdy. Carriers may classify it as Recessed End or Conventional Slotted Box.

Corrugated Common Footprint Container (CCF)

A modular-system rigid box used by most grocery supply chains. These rigid boxes are made to go directly from shipping to in-store shopping display. Interlocking notches on the sides keep stacked containers from shifting. Used for produce and meats. Sometimes called a Display Ready Case (DRC). An eco-friendly solution to former plastic carrier crates.

Comes in at least two parts: a container and a cover. One fits over the other to enclose.

Truck and rail systems classify as Telescope Style if the cover extends down over two thirds of the box depth, or Boxes with Covers if the cover extends shorter than two thirds of the box. The sturdy cover, especially with elongated sides, provides extra support.

Design Style Container with Cover (DSC)

Open box with an accompanying cover. For easy or repeated open and close, such as shoeboxes, cosmetics or jewelry, household items.

Double Cover Container (DC)

A tube forms the body, with interchangeable top and bottom covers. For products that are too heavy to load into a box, such as a refrigerator.

The Latest Technology

Pratt Industries has been at the forefront of this emerging technology, and as part of that commitment, we continue to make significant investments in digital technologies in order to better serve our customers. This includes:

- Pratt's own network of high-speed digital printers strategically located to allow us to print any type of box imagined - with nationwide reach

- High-speed roll-to-roll printing capabilities that allow us to reduce or replace preprint

- Ability to print approximately 80% of the Pantone color spectrum

1. Direct Print

- The most common method – ink prints directly onto the box

- Generally 1- to 4-color with flat graphics

- Flexo high-end direct print using CMYK + spot colors available

- Multiple-color jobs require a plate for each color

2. Spot Label

- A thin label is applied on top of the finished box surface

- May be applied to either Kraft or a White finished box

- A spot label does not cover the entire surface of the box

- A full label covers the entire surface and is used for boxes and displays that are too large or too small for a top sheet

- Lithographic print using CMYK + spot colors available

3. Top Sheet

- A litho label is applied to the single face web

- 4-color process (CMYK) as well as spot color

- Lithographic printing using CMYK + spot colors available

4. Sheet-Fed Digital Print

- Print directly to the corrugated board

- Multipass or Single Pass

- Multipass--earlier technology, slower production, generally uses UV inks

- Single Pass--newer technology and faster, uses water based inks

- Digital print using 6 color process CMYK+OV

5. Web Digital Print

- Prints only on the top liner and the liner is used in the corrugation process to create a pre-printed corrugated board

- Most modern and fastest process

- Very high-resolution graphics

- Digital print using 6 color process CMYK+OV

Flexographic (Flexo)

- Uses flexible relief plates and low-viscosity, fast-drying inks

- Works at high speeds to transfer images onto packaging material

- Can print on a variety of substrates

- Need to purchase a print plate for each color

- High-End direct printing CMYK + spots available

Lithographic

- May get efficiency in large-scale projects

- Produces high-quality packaging with sharp details and vibrant colors

Digital

- Most flexible - prints from file, not from plates

- High quality graphics with vibrant colors

- Offers larger formats, up to 110” wide

- Content can be customized

- Prints on almost any material

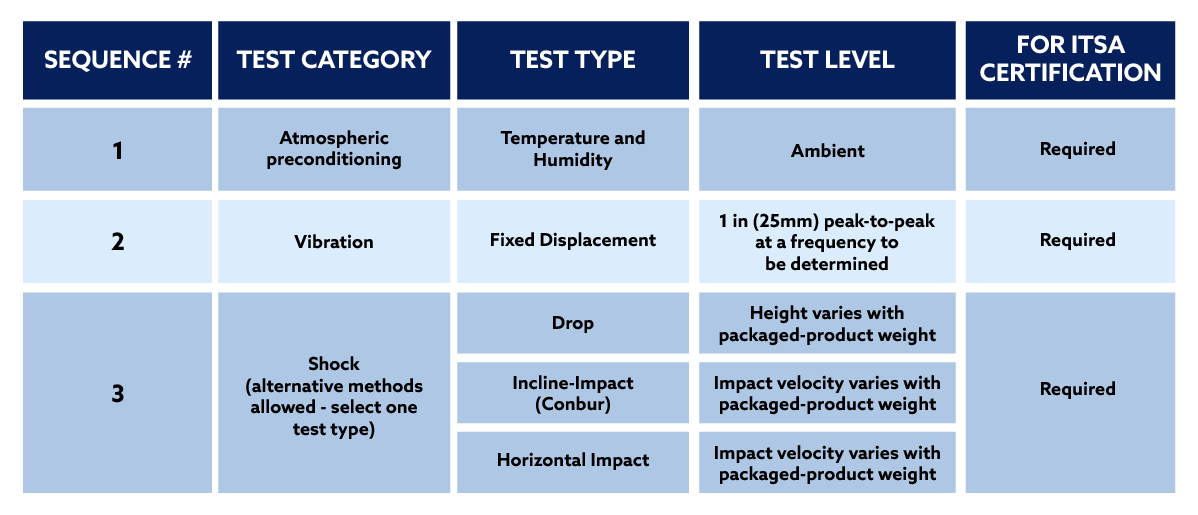

Boxes or Loads are durability tested to meet ISTA certification in Atmospheric, Vibration, Shock, Compression and Leak categories. Metric figures shown in parentheses may not be the exact equivalent of English (imperial) measurements. ISTA procedures can help to provide confidence regarding reduced damage and product loss. ISTA standards may not comply with transporter regulations.

ISTA 1A Individually Packaged Products

Tests individually packaged products weighing less than 150 lbs (68kg) in non-simulated conditions in order to meet industry standards for humidity, extremes of temperature, internal displacement, drop shock and impacts.

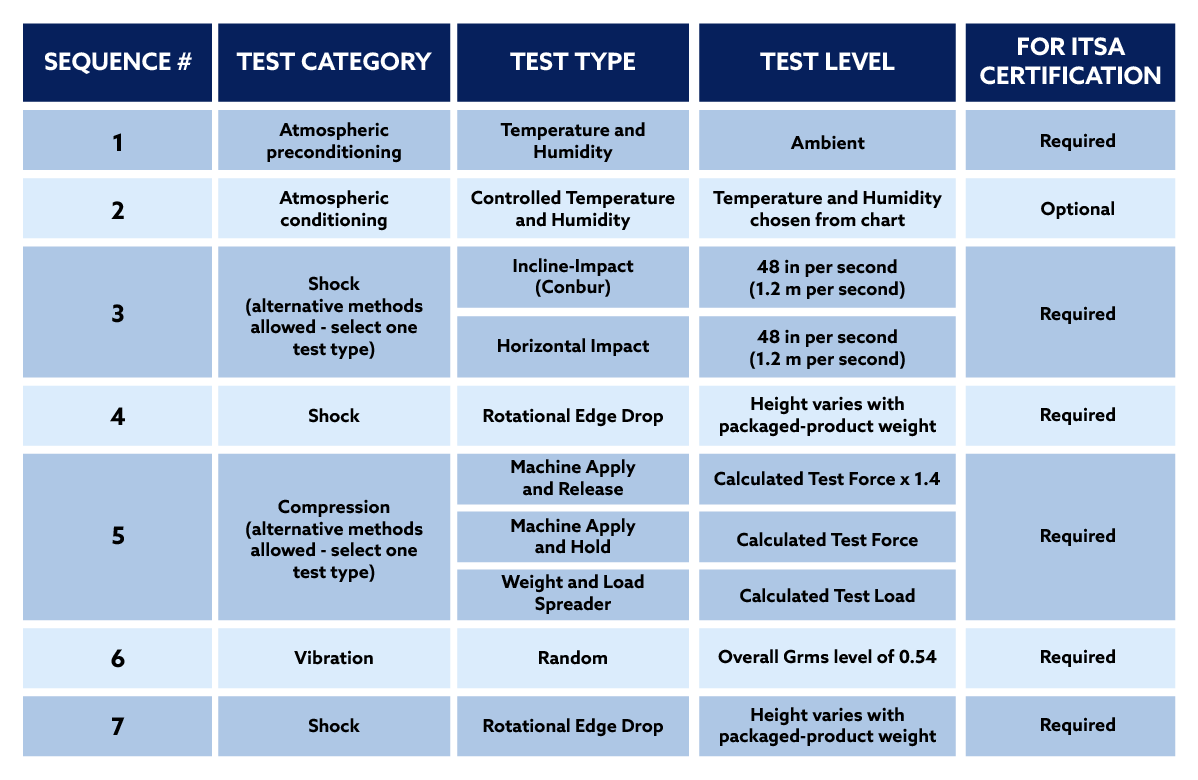

Boxes or Loads are durability tested to meet ISTA certification in Atmospheric, Vibration, Shock, Compression and Leak categories. Metric figures shown in parentheses may not be the exact equivalent of English measurements. ISTA procedures can help to provide confidence regarding reduced damage and product loss. ISTA standards may not comply with transporter regulations.

ISTA 3E Unitized Loads

Standardized machine simulation testing for unitized loads of similar retail or institutional packaged-products shipped through a motor carrier (truck) delivery system, where an entire trailer is filled with unitized, often similar, packaged products, secured to a skid or pallet. This type of shipment is called Full Truckload (FTL). Tests are performed on industry standard equipment to provide specific measurements for temperature, humidity, vibration, shock, load stability, and situations that may occur during transport and handling.

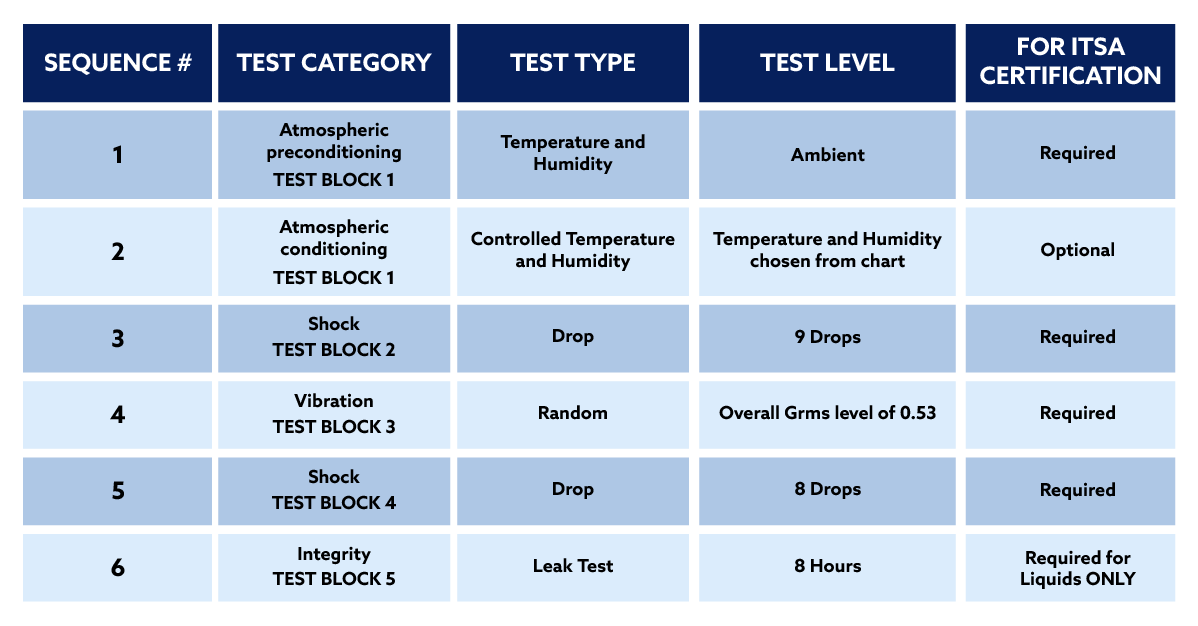

Boxes or Loads are durability tested to meet ISTA certification in Atmospheric, Vibration, Shock, Compression and Leak categories. ISTA procedures can help to provide confidence regarding reduced damage and product loss. ISTA standards may not comply with transporter regulations.

ISTA 6A Overboxed Parcels

Challenges the capability of the package and product to withstand parcel delivery transport hazards, using general simulation. Used for e-commerce fulfillment where the item is not shipped in its original container but must be over-boxed, with packing materials and sometimes with non-similar items, for shipment to the end customer. Tests atmospheric effects, drops, vibration and leakage (required for liquids). May not be compatible with carrier packaging regulations.

Boxes or Loads are durability tested to meet ISTA certification in Atmospheric, Vibration, Shock, Compression and Leak categories. ISTA procedures can help to provide confidence regarding reduced damage and product loss. ISTA standards may not comply with transporter regulations.

ISTA 7E Thermal State

Standard 7E thermal tests evaluate the effects of external temperature exposures on individually packaged products shipped via parcel delivery, by using simulations in both temperature range and time exposure. Designed to be used in combination with ISTA Standard 20, or used as a ‘standalone’ profile for general testing and qualification of an insulated shipping container.

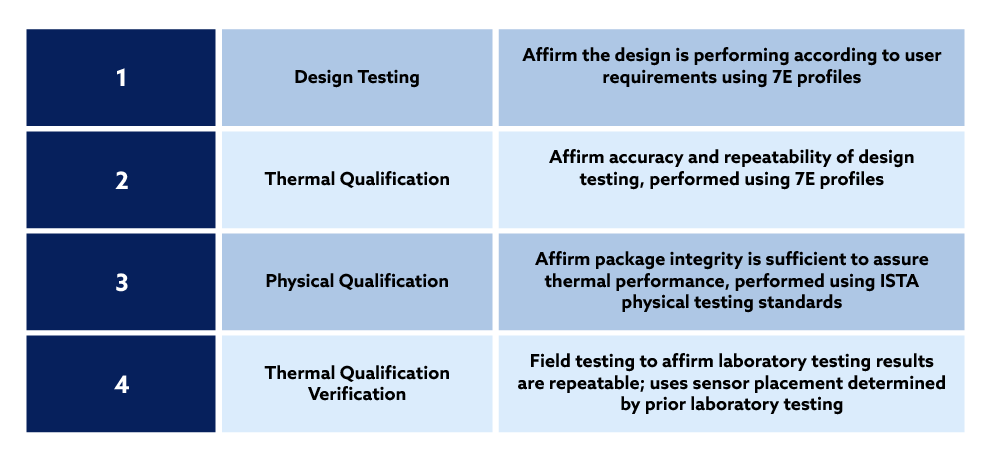

Testing Sequence

The 7E standard was developed by characterizing the transport environment and developing heat and cold profiles to test packaging configurations. Profiles are provided for heat and cold, and for 72 hour and 144 hour durations.

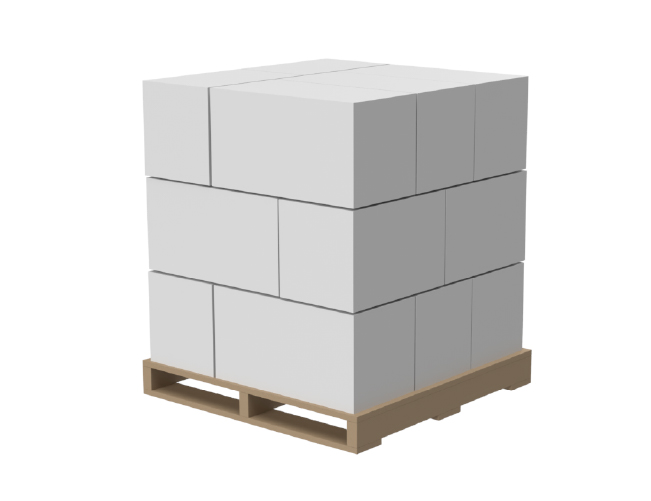

‘Cubing the trailer out’ uses load planning to arrange freight in such a way as to minimize wasted space and to balance the load. This is done by taking into account the size, shape and weight of the shipment in relation to the dimensions and weight capacity of the trailer.

- Trailer Capacity - Max Weight - 45,500 lbs.

- Trailer Capacity - 3,800 cubic feet

- Trailer Capacity - standard-sized (48″ x 40″ x 48″)

- A 53-ft truck can fit 26 non-stackable pallets and 52 stackable, standard-size pallets.

Column stacking places one box of the same size exactly on top of another. These columns are then placed side by side. This method maximizes the multi-angled strength of box corners, but unless the boxes are bound together, shifting can cause a loss of as much as 30% of a supporting box’s strength, which can cause toppling. This is the only stacking method available for square boxes.

Interlocking stacking is an option for rectangular boxes that rotates the way loads are layered, so the shorter side of a box sits on top of the wider side of the box underneath it, and vice versa. This shifting pattern lessens the likelihood of toppling. Yet, there is a 50% loss of box strength because the strongest part of the box - the corners - are not aligned on top of each other. Damage to individual boxes may be higher.

WHAT'S YOUR GOAL?

The best part of Pratt? We go way beyond the box.

Save time by easily plugging into Pratt's Customer Team -- we are over 300 strong!

- Answer six questions.

- You'll be contacted by an account rep who thinks beyond the packaging needs, to be sure you'll get exactly what you want.

WHAT'S YOUR

GOAL?

The best part of Pratt? We go way beyond the box.

Save time by easily plugging into Pratt's Customer Team -- we are over 300 strong!

- Answer six questions.

- You'll be contacted by an account rep who thinks beyond the packaging needs, to be sure you'll get exactly what you want.