PARTNER WITH PRATT

TO IMPROVE EFFICIENCIES

CASE STUDIES

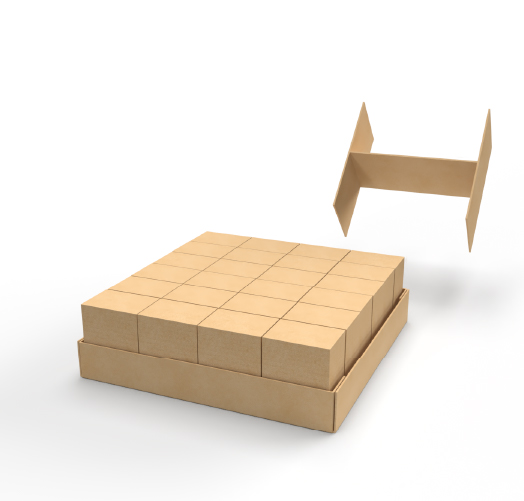

Maximize Capacity

In partnering with our VIP team, did you know you can maximize the amount of boxes you are able to get on a truck utilizing our D flute technology?

D-Flute is a smaller, more compact packaging option, which helps optimize space, throughput, and efficiency. This allows up to 30% more available space to package products, meaning customers have less boxes to handle and stack. In turn, this increases the capacity of warehouse space and allows for logistic gains, meaning more boxes fit on a truck. This can also help with your sustainability efforts as fewer trucks lead to a reduction in CO2 emissions.

Reduce Operating Costs

Material Cost Savings

Pallet Cost Savings

Warehouse Cost Savings

Freight Cost Savings

Partnering with our Value Improvement Program (VIP) team, a customer was able to reduce costs across its operations, including material, pallets, warehouse and freight. Pratt experts partnered with the customer to evaluate packaging, shipping and storage requirements for nearly 200 items. The Pratt team then performed tests to understand how changing containerboard grades, packaging dimensions and pallet configuration affected the items and overall supply chain costs. Based on these studies, Pratt recommended using less corrugated material more efficiently and optimizing the balance of case stacking on pallets. The result was more cases per pallet layer and a reduction in truckloads to create substantial savings in material, warehousing and freight.

Optimize Production

A food manufacturer needed to increase productivity. The current process was for employees to hand stack trays onto its production line. Pratt partnered with the customer to evaluate the benefits and costs of adding automation to the line. By working with OEMs (original equipment

manufacturers), Pratt was able to test multiple options to determine the most efficient and cost-effective solution for the customer. The result was increased productivity and reduced labor costs by reassigning the employees to other areas of need.

Reduce Transportation Costs

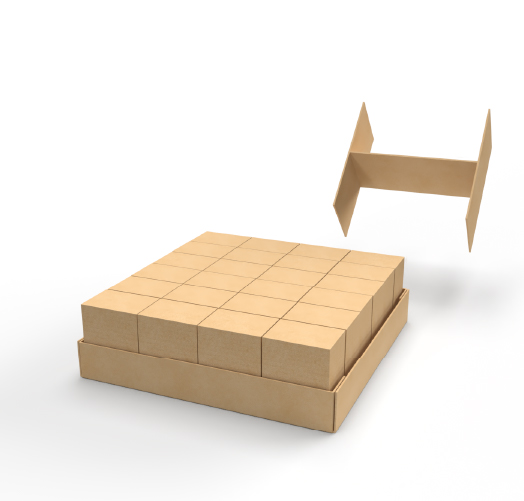

From RSCs...

TO PALLET TRAYS WITH PARTITIONS

A customer was placing each product into separate primary packaging then placing those packages into regular slotted containers (RSCs) to be loaded onto pallets and shipped to a fulfillment center. Once products were distributed, the fulfillment center was then throwing away approximately half of the RSCs. Pratt was able to redesign the packaging, using a combination of pre-glued, in-fold layer trays and partitions for load support. The result was a reduction in RSCs used, and therefore discarded, labor savings and a solution that still protected the products throughout the transportation and storage process.

Get to Market Faster

Current:

AIR FLOW BLOCKED

PROPOSED:

AIR FLOWS THROUGH

A customer's work-in-progress took up significant space and was a bottleneck to getting product out the door. The customer used corrugated vents and bags for its work-in-progress bins. Pratt’s team found that the ventilation in the bins was poor due to few and unaligned vent holes obstructing proper airflow and leading to longer cure times. The recommendation included vent holes that lined up in reusable corrugated bins and changing the venting in the bags to reduce contaminants. The result was a reduced cure time which created faster throughput and greater availability of product in the market.

Maximize Capacity

In partnering with our VIP team, did you know you can maximize the amount of boxes you are able to get on a truck utilizing our D flute technology?

D-Flute is a smaller, more compact packaging option, which helps optimize space, throughput, and efficiency. This allows up to 30% more available space to package products, meaning customers have less boxes to handle and stack. In turn, this increases the capacity of warehouse space and allows for logistic gains, meaning more boxes fit on a truck. This can also help with your sustainability efforts as fewer trucks lead to a reduction in CO2 emissions.

Reduce Operating Costs

Material Cost Savings

Pallet Cost Savings

Warehouse Cost Savings

Freight Cost Savings

Partnering with our Value Improvement Program (VIP) team, a customer was able to reduce costs across its operations, including material, pallets, warehouse and freight. Pratt experts partnered with the customer to evaluate packaging, shipping and storage requirements for nearly 200 items. The Pratt team then performed tests to understand how changing containerboard grades, packaging dimensions and pallet configuration affected the items and overall supply chain costs. Based on these studies, Pratt recommended using less corrugated material more efficiently and optimizing the balance of case stacking on pallets. The result was more cases per pallet layer and a reduction in truckloads to create substantial savings in material, warehousing and freight.

Optimize Production

A food manufacturer needed to increase productivity. The current process was for employees to hand stack trays onto its production line. Pratt partnered with the customer to evaluate the benefits and costs of adding automation to the line. By working with OEMs (original equipment

manufacturers), Pratt was able to test multiple options to determine the most efficient and cost-effective solution for the customer. The result was increased productivity and reduced labor costs by reassigning the employees to other areas of need.

Reduce Transportation Costs

From RSCs...

TO PALLET TRAYS WITH PARTITIONS

A customer was placing each product into separate primary packaging then placing those packages into regular slotted containers (RSCs) to be loaded onto pallets and shipped to a fulfillment center. Once products were distributed, the fulfillment center was then throwing away approximately half of the RSCs. Pratt was able to redesign the packaging, using a combination of pre-glued, in-fold layer trays and partitions for load support. The result was a reduction in RSCs used, and therefore discarded, labor savings and a solution that still protected the products throughout the transportation and storage process.

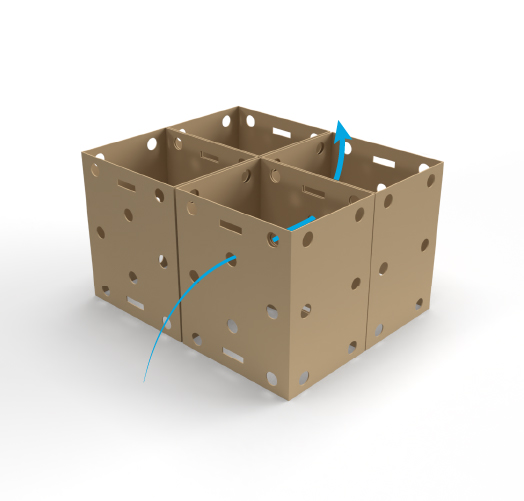

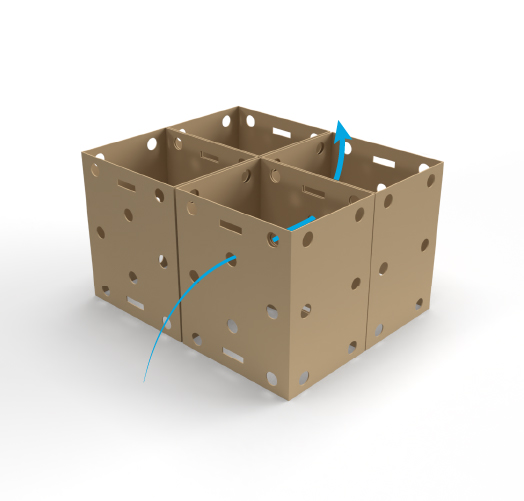

Get to Market Faster

Current:

AIR FLOW BLOCKED

PROPOSED:

AIR FLOWS THROUGH

A customer's work-in-progress took up significant space and was a bottleneck to getting product out the door. The customer used corrugated vents and bags for its work-in-progress bins. Pratt’s team found that the ventilation in the bins was poor due to few and unaligned vent holes obstructing proper airflow and leading to longer cure times. The recommendation included vent holes that lined up in reusable corrugated bins and changing the venting in the bags to reduce contaminants. The result was a reduced cure time which created faster throughput and greater availability of product in the market.

WHAT'S YOUR GOAL?

The best part of Pratt? We go way beyond the box.

Save time by easily plugging into Pratt's Customer Team -- we are over 300 strong!

- Answer six questions.

- You'll be contacted by an account rep who thinks beyond the packaging needs, to be sure you'll get exactly what you want.

WHAT'S YOUR

GOAL?

The best part of Pratt? We go way beyond the box.

Save time by easily plugging into Pratt's Customer Team -- we are over 300 strong!

- Answer six questions.

- You'll be contacted by an account rep who thinks beyond the packaging needs, to be sure you'll get exactly what you want.

FOR EVERY PACKAGING CUSTOMER

OUR PROCESS IS THE SAME

Custom Sustainable Packaging Solutions

You First

- Your Requirements

- Your Challenges

- Your Line Design

- Your Throughput Goals

Our Team Steps Up

- Our Experience

- Our Capabilities

- Our Capacity & Reach

Our Plants Go to Work

- Recycled material

- Containerboard

- Custom Boxes

- Palletized Truckloads

- We source & manufacture what you want

We Deliver

- Full-Service Logistics

- Dedicated, Agile Fleet

- Broker with Other Carriers

- Shipping Agent

- Supply-Chain Control

Recycling

- Manage Waste

- Achieve Your Net Zero Objectives

FOR EVERY PACKAGING CUSTOMER

OUR PROCESS IS THE SAME

Custom Sustainable Packaging Solutions

You First

- Your Requirements

- Your Challenges

- Your Line Design

- Your Throughput Goals

Our Team Steps Up

- Our Experience

- Our Capabilities

- Our Capacity & Reach

Our Plants Go To Work

- Recycled material

- Containerboard

- Custom Boxes

- Palletized Truckloads

- We source & manufacture what you want

We Deliver

- Full-Service Logistics

- Dedicated, Agile Fleet

- Broker with Other Carriers

- Shipping Agent

- Supply-Chain Control

Recycling

- Manage Waste

- Achieve Your Net Zero Objectives

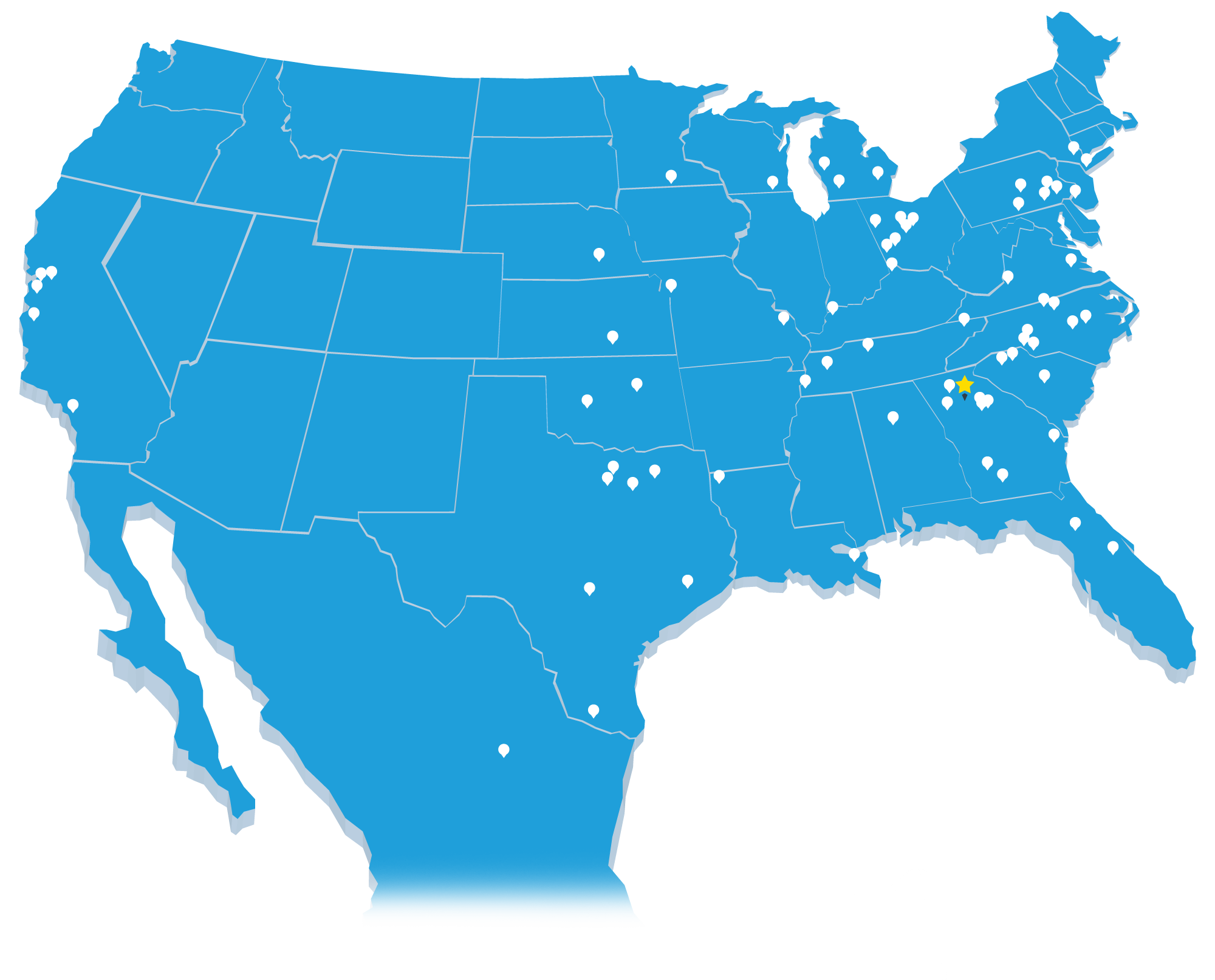

NATIONAL FOOTPRINT. LOCAL SERVICE.

Your packaging goals drive our solutions.

- Pratt has created a technically advanced hub-and-spoke network

- Our strategically placed plants throughout the US allow for ease of access to packaging when you need it

- Pratt owns and manages its own truck fleet and logistics

Manufacturing Divisions

NATIONAL FOOTPRINT

LOCAL SERVICE

Your packaging goals drive our solutions.

- Pratt has created a technically advanced hub-and-spoke network

- Our strategically placed plants throughout the US allow for ease of access to packaging when you need it

- Pratt provides full-service logistics locally, regionally and nationally